Ignition Mods Page 2 - Go to Page one two three

The search for a bit more pick-up (without more fuel-up)

Having fixed the vacuum retard unit and finding some improvement, I felt more could be done to this emissions strangled engine and started thinking about Mike Morrin's data.

Mike said, "It would appear that 1975 cars would benefit from a bit more centrifugal advance (as per 76-on)." and this got me pondering - well, some things do that to me.

Now an injected pre-HE XJ V12 doesn't need vacuum retarded ignition at idle as the fuel injection overcomes the problems. It is fitted with an ignition vacuum advance module and with the extra centrifugal advance that Mike mentioned, I wondered how this set-up would work on my earlier V12 with carb's.

My car's idle was quite acceptable down to 300 rpm. The centrifugal advance uses the same springs and weights, but the take-off on the carb for the vacuum retard module cannot be used. A new port is needed on the opposite side of the throttle butterfly. This means modifications to the carb's are also needed (page 3). The following communication with Roger Bywater (a former Jaguar factory engine developer who worked on the V12's development and now runs a V12 tuning firm) confirmed my thoughts:

From Roger Bywater of AJ6 Engineering

"The centrifugal advance mechanism has only one function - to advance the timing with rising engine speed in a manner that approximates, as far as a mechanical system can, to the ideal engine requirement for the full throttle condition.

Vacuum retard has two purposes. Firstly as an emission control device - by retarding the timing the exhaust temperature rises, promoting after-reactions in the exhaust, with or without a catalyst or air pump. This also can cause the engine to run hotter so most early V12 engines have a temperature switch on the water rail to dump the vacuum retard signal if the coolant temperature rises too much. The other purpose of a retard system is to provide a very stable idle condition - if the engine speed begins to fall the vacuum drops so the retard is reduced and the engine speed picks up. This is often helpful to deal with power steering and air conditioning load changes at idle.

Vacuum advance from an opening throttle edge port is usually arranged to have no effect at idle but then pulls vacuum onto the capsule as the throttle edge moves outwards past the vacuum port. As the throttle opens further the vacuum follows manifold pressure and the advance does the same so at full throttle or under heavy acceleration there should not be any vacuum advance at all. Some systems have a dump valve to ensure that this is so by venting the system completely. It therefore should not have any effect on the full load advance provided by the centrifugal mechanism and has no effect on pinking or detonation (not the same thing) which are generally conditions which only occur at or close to full throttle. The purpose of vacuum advance is to advance the timing in part load and cruise conditions which improves fuel economy.

Vacuum advance can also be provided from a manifold pressure tapping which makes it possible to have it applied at idle as a further aid to economy, however it does introduce a risk of idle instability, having the opposite effect of idle retard, and can also cause a deterioration of idle quality because the spark occurs too far before the piston has completed the compression process. My recollection is that the carb V12 in particular does not idle well with much vacuum advance.

I am sure you will be aware that some engines have vacuum capsules with advance as well as retard capability to try to get the best of all worlds.

The 6-10-8 advance capsule from the pre-HE injection engines would probably work well but the HE capsule has more advance which may cause loss of driveability. Whichever vacuum system is used the centrifugal advance should be set at the correct figure recommended by Jaguar for the fuel quality in use."

I decided to try it. The modifications would be easily reversible if it didn't work.

The easy way would be to swap the vac module for one from a pre-HE XJ or XJ-S, so I got one from a scrap yard but it was leaking so I did my "handbag" repair to it. I’ve heard that MG-B vac advance modules will fit, but I don’t know what the advance travel and vacuum requirement is (i.e. strength of internal spring). One could be opened up and the material used perhaps.

An important point here. Where the plastic pick-up carrier rotates around the body of the distributor is prone to wear. On mine it had worn a ridges which would've held back the movement of the carrier when the vacuum advance mechanism tried to move it.

I simply filed the ridges down to a smooth curve, applied moly grease and had no problem.

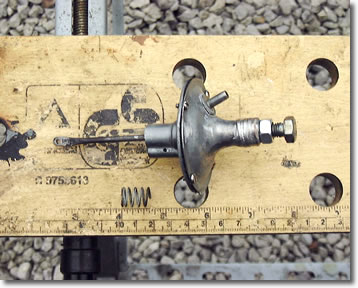

The photos in the Modifications Gallery show the vacuum advance module dismantled. In one photo, the pushrod on the right is the original which was peened over at the end to hold washers on. As stated above, this was useless after dismantling, so I got a long threaded bolt from an old alternator and used the threaded end with a couple of nuts and Loctite to hold the diaphragm washers. I daresay a spoke from a motorcycle wheel may provide a suitable alternative. I then cut the length to match and heated and flattened the other end. I drilled a hole in the flat end to locate over the spigot on the distributor. The same photo shows the nylon material with it’s silicon rubber coating and the “bell” of the module.

Test driving with the standard XJ-S advance module showed a definite improvement in light-throttle acceleration, the trouble was it would come in suddenly and a bit too late then it faded quickly on squeezing the pedal further. So what was wrong?

I don't know of any figures, but my guess is that a fuel injected engine is drawing air through two throttles but a carb engine is drawing through four. This may result in lower vacuum in the carb venturis when the throttle butterflies are just opening. Alternatively, it may just be down to the position of my "looks about right" throttle edge tapping in the carb. Whatever the reason, I just wasn't getting enough vacuum to operate the module satisfactorily at small throttle openings.

I decided that reducing the strength of the spring that returns the advance diaphragm by shortening it (see cut off portion in photo below) would allow it to start advancing earlier (i.e. lower vacuum readings) and remain advanced for longer.After shortening the spring, I re-checked the start-end vacuum readings by temporarily fitting it all together then sucking on the module with a tube and a vacuum gauge in the line. I had done this check before I shortened the spring and it seemed fine, but vacuum required to operate it was possibly a little higher than specified in Mike Morrin's data. Sucking through a tube isn't exactly scientific measurement!

As I was experimenting with this module I also decided to try an adjustable travel set up, as used on some older types of vacuum advance to vary the number of degrees of advance the module gives.

My vacuum advance unit showing the nut and bolt travel adjustment modification, and the length of diaphragm spring cut off the original (larger photos in the Modifications Gallery).

I drilled a suitable hole in the end of the module where the spring seats. I soldered a nut to the outside of the “bell”, but it broke off. I simply re-soldered it with a reinforcement of braided de-soldering wire wrapped around the joint and tinned it all - no trouble since. Through this nut I used a bolt to act as a stop on the diaphragm. I ground off the threads on the end of the bolt that slips through the spring to make sure they didn't bind on the spring. The nut you see in the photo above is just a locking nut - the main one is under the braid-wrapped reinforcement. I used semi setting blue Hermetite on the thread of the bolt to keep it airtight.

Turning the bolt allows me to increase (or decrease) the amount of vacuum advance several degrees more than the original unit. I measured the original’s travel before dismantling (more later), and ground smooth the threads of the bolt where the spring goes over it. I have set it to give about four or five degrees more than standard and have no pinking.

To measure the travel, I put the unmodified XJ-S vacuum advance module in the distributor and, by mounting a protractor with a bit of “Blue Tack” on top of the rotor arm, measured the amount of travel in degrees on the vacuum advance module (by connecting a tube to the module and sucking through it). This gave me a base measurement to work from when I completed the adjustable travel module. I ended up setting it with just a couple of degrees more advance on the vacuum module than standard and found this just about right.

The result was as I hoped, the acceleration from rest was more continuous and I’m very happy with it. Of course, foot-to-the-floor acceleration is, as Roger states, no different. The difference is in normal traffic and cruising acceleration where not as much "pedal" is required to give the desired result. It gives a livelier town driving performance and saves fuel. This part throttle improvement also gives better economy when cruising at higher speeds.

I haven’t done anything further with this experiment as I haven’t had the time and it’s running great anyway. It may or may not be possible to fine tune the ignition curves further. If anyone reading this wants to have a go on their own car, I would recommend trying an vacuum advance module modified like mine (cheap enough to experiment with if you get one from a breaker), but even an unmodified standard pre-HE XJ12/XJS advance module should show some improvement. To be honest, I can't remember whether I increased the static timing on mine or not - I think I have it set at a few degrees more than spec. around 3,000 rpm.

When I do get a round tuit, I shall sort out exact start-end-degrees specifications for the modified vacuum unit and the exact measurements for the necessary throttle-edge vacuum port in the carburettor. I shall also check the centrifugal timing and put the details on the site. Now go to page 3 to see how I dealt with the carbs.

Ignition Mods Page 2 - Go to Page one two three

This site is for the benefit of enthusiasts. Much of the content is my own to use as you wish. However, some I have collected from various (forgotten) sources in the public domain. If you are the owner of any material used and wish it to be removed or so accredited, please contact me.

Web Site © Double Six Design

|